Planter Closing Wheels that Last

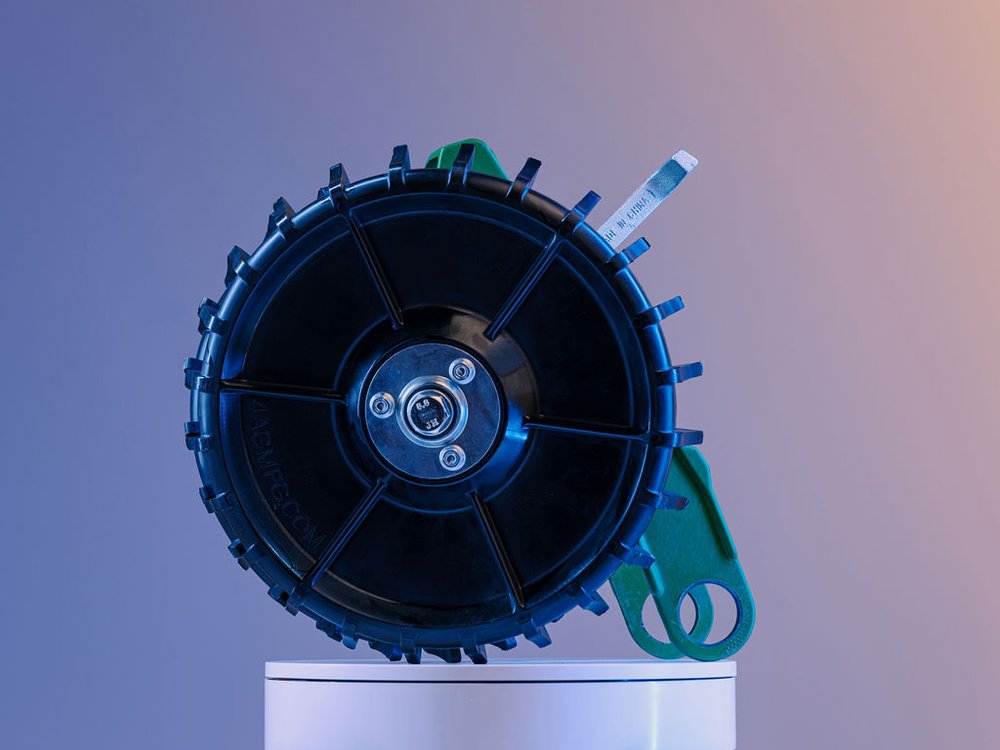

The 4Ag planter closing wheel was designed by farmers for farmers to ultimately increase emergence by improving seed-to-soil contact, leaving a soft-tilled surface as a result.

Made from the same patent pending tough proprietary composition as our gauge wheels, our fully assembled closing wheel includes a bolt kit with spacers to provide easy installation with multiple adjustments accommodating a variety of planting conditions.

Closing Wheel Specs

After we created the planter gauge wheel, we felt the natural next step was to build the companion closing wheel that would withstand the same amount of wear and tear. Thus, our planter closing wheels were born!

Closing Wheel Features

- 24 tillers per wheel

- Weight: 10.14 lbs per row

- Diameter: 13 ⅞ inches

- Easy installation, less downtime with no press required

- Solid tire made from a patent-pending tough proprietary composition

- Added UV protection

- Fits all old and new style no-till planters

- Made to fit your no-till planter

By Farmers, For Farmers

Our closing and planter gauge wheels are strategically created for no-till farmers who work in a number of crops, including:

- Cotton

- Soybean

- Corn

- Milo

- Wheat

- Sunflowers

- & more!

There isn’t a no-till crop our wheels can’t handle.

Us vs. The Other Guys

We’ve been farming no-till cotton in western Oklahoma for years. Unfortunately, the other guys’ products just weren’t cutting it. We were replacing wheels annually, and our equipment was damaging our crops.

We took matters into our own hands and built products that are meant to last.

In addition to our gauge wheel, we constructed a complimentary closing wheel that can upgrade your no-till planter.

Our unique design includes added tiller tines that till roughly the top quarter inch of the soil leaving the ground surface loose to prevent baking in wet conditions while also eliminating the need to add additional equipment such as a harrow or drag chain. Tilling the surfaces mulches the crack where the two sides of the trench come together, ensuring full closure of the seed trench.

See it for yourself!

Competitors

4ag closing wheel

Reviews from Our Ranchers

Our products are built with farmers in mind. Take a look at what our customers have to say!

Break the Cycle

We’re in your shoes.

We know you’re replacing your planter gauge wheels way too often. No-till planting is no joke. It wears on your machinery. As a farmer, you want the best for your land and crops. When your land is harsh on your equipment and vice versa, it can put you in a cycle of constantly spending time and money to replace parts.

Your wheels are key to upgrading your no-till planter, and you want something that can help you get the job done.

That’s where our closing wheels come in! Make a purchase you won’t need to rebudget for next year.

Frequently Asked Questions

What is a closing wheel wheel, and what does it do?

A closing wheel is attached to a no-till planter and is responsible for pressing soil back over the seed after it’s been placed in the furrow. This process ensures good seed-to-soil contact, which promotes proper germination and early root development.

How do I choose the right closing wheels for my no-till planter?

Spiked wheels are often used in no-till systems to break up compacted soil. Check your manufacturing information before purchasing, but our wheels fit most old and new no-till planters.

What are the benefits of using spiked or finger closing wheels?

Spiked or finger closing wheels are beneficial in heavier, compacted soils or no-till conditions. They break up soil around the seed trench and help close it without excessive compaction, which can improve emergence in challenging conditions.

How do I adjust closing wheels on my no-till planter?

Closing wheels are typically adjusted by setting their angle and downforce to achieve the desired soil coverage. Proper adjustment depends on soil type and moisture levels, so it’s a good idea to test adjustments in your field before planting.

How do I know if my closing wheels are properly adjusted?

Properly adjusted closing wheels will leave the seed trench completely closed with no visible air gaps or exposed seeds. If you see seeds on the surface, inconsistent coverage, or excessive compaction, adjustments may be needed.

What signs indicate it’s time to replace my closing wheels?

If you notice excessive wear, cracks, or missing spikes (for spiked wheels), it may be time to replace them. Worn closing wheels may not close the seed trench effectively, which can lead to poor germination and crop emergence.

How do I maintain my closing wheels?

Regularly clean and inspect your closing wheels, especially after planting in muddy or debris-filled conditions. Check for wear or damage, ensure proper alignment, and store them in a dry location when not in use.

What is downforce, and how does it affect closing wheels?

Downforce is the pressure applied by the planter on the closing wheels to press the soil over the seed. Too much downforce can lead to soil compaction, while too little can leave the seed trench partially open. Adjust downforce based on soil conditions for optimal results.

How do closing wheels perform in wet or sticky soil conditions?

Spiked or notched wheels can be better in these cases, as they’re designed to minimize soil buildup and maintain effective closure.

How do I prevent soil compaction with closing wheels?

To avoid soil compaction, adjust the downforce according to the soil’s moisture level and condition. Spiked or notched closing wheels also help reduce compaction by breaking up the soil instead of pressing it down too firmly.

What is the difference between a gauge wheel and a closing wheel?

A gauge wheel sets and maintains the seed planting depth, while a closing wheel presses the soil back over the seed after it’s placed. Both wheels are essential for effective planting but serve different functions.

Join our community

Want to see what we have coming down the pipeline? Interested in seeing our tools in action?

From behind-the-scenes to events for Oklahoma farmers and more, we give you an inside look to 4Ag over on Facebook.