Everything You Need to Know About Planter Closing Wheels

A planter closing wheel may not look like much, but in farming it makes all the difference. This simple part presses soil over the seed furrow, creating the seed-to-soil contact that every crop needs to germinate. Without the right closing wheel setup, you risk uneven stands, wasted seed, and lower yields.

Farmers today are expected to do more with less—less time, less fuel, and fewer chances to replant. That means every pass counts, and so does every component of your planter. This guide explains what planter closing wheels are, how they work, the different types available, how to pick the right ones for your soil, and how to maintain them for peak performance.

What Is a Planter Closing Wheel?

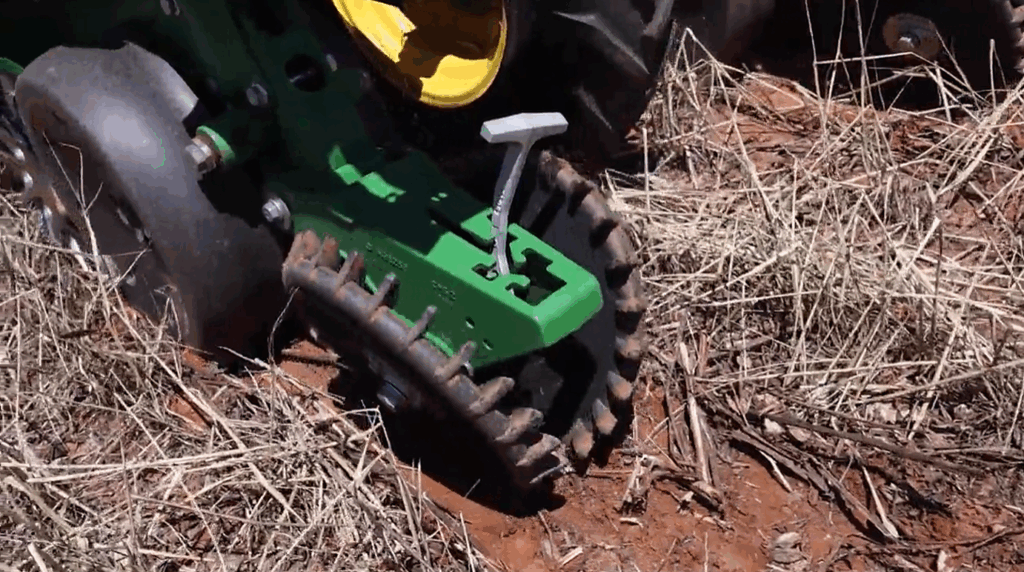

A planter closing wheel is an attachment mounted behind the planter’s seed opener. Once the seed is placed at the correct depth, the closing wheel presses soil back over the furrow.

Its main jobs are:

Cover the seed fully with soil

Ensure consistent seed-to-soil contact

Remove air pockets that slow germination

Manage moisture by sealing the furrow

Without effective closing wheels, the seedbed is inconsistent. Some seeds are left too shallow or exposed, others are buried too deep. Both outcomes hurt uniform emergence, and uneven stands make crop management harder all season.

How Does a Closing Wheel Work?

Closing wheels trail behind the planter opener, pressing and firming soil over the seed. Their design—rubber, spiked, poly, or cast iron—determines how they handle soil conditions. The right wheel creates a sealed but not compacted furrow, which is critical for germination.

Why Do Planter Closing Wheels Matter?

Consistent Seed Germination

Uniform stands are the foundation of strong yields. If half your field comes up three days late, it drags down overall crop health. Closing wheels eliminate air pockets and keep soil tight against each seed, encouraging fast and uniform sprouting.

Soil Compaction Control

Good wheels balance aeration and compaction. Too much compaction, and roots struggle to expand. Too little, and moisture escapes. Closing wheels hit the sweet spot—firm enough to seal the furrow but not so firm that the seedling is trapped.

Moisture Retention

In dry years, keeping moisture close to the seed can make or break a stand. Closing wheels that seal furrows properly help hold in valuable water.

Efficiency and Profitability

Better germination means fewer replant passes, less wasted seed, and stronger yields. Even though closing wheels are a small investment compared to your planter, they pay back quickly by saving inputs and boosting output.

Types of Planter Closing Wheels

Different soils demand different closing wheel designs. Here’s a rundown of the most common types:

Rubber Closing Wheels

Best for: Softer, well-tilled soils

Benefits: Moderate pressure, affordable, simple

Watch out for: Struggles in hard or wet soils

Spike Closing Wheels

Best for: No-till or compacted soils

Benefits: Spikes break up clods, improve aeration, and close furrows in tough ground

Watch out for: Can be too aggressive in light soils

Cast Iron Closing Wheels

Best for: Heavy clay or very dry soils

Benefits: Extra weight punches through hard ground

Watch out for: Risk of over-compaction in mellow soils

Poly Closing Wheels

Best for: Wet, sticky soils

Benefits: Don’t clog with mud, lightweight, corrosion resistant

Watch out for: Not as aggressive in rocky or compact soils

How Do You Choose the Right Planter Closing Wheel?

Match to Soil Type

Sandy or loam = Rubber or poly

Heavy clay = Cast iron or spike

No-till = Spike

Consider Weather Patterns

If your fields tend to be muddy in spring, poly wheels will shed soil better. If you plant in drier conditions, cast iron gives the weight you need.

Think About Crop Type

Corn, soybeans, and cotton all have slightly different planting depths and furrow-sealing needs. Adjust wheel choice (and down pressure) accordingly.

Factor in Durability

Choose materials built for your soil. Poly resists corrosion, iron lasts decades in dry soils, rubber is easy to replace but wears faster.

Maintenance Tips for Planter Closing Wheels

Even the best wheel won’t perform if it’s worn out. Here’s how to keep yours in shape:

Inspect frequently – Check for cracks, bends, or missing spikes

Lubricate bearings – Grease as recommended to avoid seizing

Adjust pressure – Match downforce to field conditions

Keep them clean – Wash off mud, fertilizer, and residue after planting

Replace when worn – Don’t limp through a season with bad wheels; it costs more in lost yield

Question Farmers Ask: How Do I Know If My Closing Wheels Are Working?

If you see open furrows, delayed emergence, or inconsistent stands, your wheels aren’t sealing properly. Dig behind the planter after a few rows. The seed should be snug, with no air gaps, and covered evenly with moist soil. If you can see the seed or if the soil falls away easily, your closing wheels need adjustment—or replacement.

Modern Innovations in Planter Closing Wheels

Technology is pushing even small parts like closing wheels forward.

Self-cleaning treads prevent mud build-up

Adjustable systems let farmers swap wheels for different soils

Electronic downforce sensors automatically adjust wheel pressure in real-time, improving consistency across variable fields

This adaptability means farmers don’t have to compromise when moving from one field condition to another.

The Role of Closing Wheels in Soil Health

Long-term, the right closing wheel setup doesn’t just help germination—it also supports soil structure and health. Proper furrow closure reduces erosion, improves water infiltration, and encourages deeper root systems. That translates into stronger, more resilient crops season after season.

Michigan State University Extension offers solid advice on how to reduce sidewall compaction—such as using one spiked wheel and one standard wheel per row, adjusting down-pressure wisely, and leveling the planter—to ensure optimal seed-to-soil without smearing the furrow.

Why Farmers Trust 4AG Planter Closing Wheels

At 4AG Manufacturing, our wheels are designed with farmers in mind:

Durable construction to withstand tough soils

Corrosion-resistant materials for long life

Options for all soils—rubber, spike, cast, and poly

OEM compatibility for fast, hassle-free replacement

Browse our planter closing wheels to find the right fit for your planter.

Conclusion

The planter closing wheel is one of the smallest parts of your planter, but it has one of the biggest impacts on your crop. From sealing moisture in to ensuring uniform stands, the right closing wheel setup can add bushels to your yield and save you time in the field.

Ready to equip your planter with the best wheels for your farm? Visit our Dealer Locator or reach out on our Contact page to learn more about becoming a 4AG dealer today.

This article was generated with the assistance of artificial intelligence (AI). While reviewed for accuracy and clarity by 4Ag, it should be considered general information. We still recommend contacting the 4Ag team for personalized advice.